Introduction

We have all seen CNC plasma cutting machines used in factories, warehouses, and other industrial buildings. They are becoming more and more popular, with many businesses leasing or buying one for its speed and ease of use. In this article, you’ll get to know more about CNC plasma cutting machines.

What is a CNC Plasma Cutting Machine?

A CNC Plasma Cutting Machine is a machine that uses plasma to cut materials. There are several types of CNC Plasma Cutting Machines, but all of them share some common features.

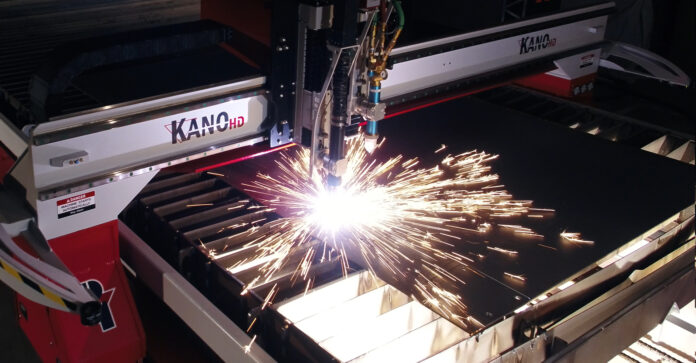

First, all of these machines use a plasma torch to cut the material. This is a very hot type of flame that cuts through materials very quickly.

Second, all of these machines use a computer to control the cutting process. This allows the operator to make precise cuts in difficult locations.

Finally, all of these machines use software to control the cutting process. This allows the operator to create complex patterns and designs in the material that they are cutting.

The Advantages of Using a CNC Plasma Cutting Machine

If you’re in the market for a CNC plasma cutting machine, there are a few things to keep in mind. Here, we’ll outline some advantages of using a plasma cutter over other cutting methods, including:

— Increased efficiency – They are much more efficient than traditional knife cuts, resulting in faster production times.

— Reduced costs – Because the CNC Plasma Cutting machine is able to cut through multiple materials simultaneously, it can save you money on supplies.

— Improved quality – thanks to the precision of the cuts, your products will be of higher quality than those cut with a traditional knife.

— Increased safety – because the machine operates at high temperatures, it is safe for both operators and customers.

How does a CNC Plasma Cutting Machine Work?

A CNC plasma cutting machine is a cutting machine that uses high-power beams of plasma to cut materials. This machine is used to create intricate and detailed shapes in various materials, such as metal, plastic, and wood.

To use this machine, you first need to input the desired shape into the computer. The computer then controls the high-power beams of plasma to cut the material precisely. This process is very accurate and can be used to create intricate and detailed shapes. Because this machine is so precise, it is often used to create products that are difficult or impossible to make with other types of machines. They can be used to create intricate designs in metal. Other machines can only create simple patterns or lines in the metal.

Overall, a CNC plasma cutting machine is an extremely versatile tool that can be used to create a wide range of products. It is perfect for creating detailed and intricate shapes in various materials.

Final words

CNC plasma cutting machines are incredibly versatile and can be used for a variety of projects. They also tend to be very reliable and offer high levels of accuracy, which is especially important when it comes to precision tasks like crafting delicate objects or cutting materials accurately. Finally, they can take a lot of punishment and still operate at peak performance. If you’re looking for an investment that will pay off in the long run, look no further than a CNC plasma cutting machine!